OVERVIEW

INFRAMAX General Contracting are dealing with ‘‘HORIZONTAL DIRECTIONAL DRILLING’’ by latest and

modern technologies, capable to work on hard rocks, sand areas and under water. Innovative processes for laying out pipes such as HDPE and Carbon Steel with well qualified personnel who can assist in finding solution in any type of boring works with the most suitable Horizontal Drilling Machine along with a number in many advantages like trenchless, ecological, economical, safe, and fast way of boring results.

BORING PATH

The bore path entry pit to exit pit must be planned before the boring begins. It can be marked on the ground with chalk dust or written in paper for operator references. For complicated bores it must consult to engineer, have job site surveyed and bore path calculated. Be sure engineer knows the minimum entry pit bend limits of drill pipes and pullback material, pipe lengths and location of all underground utilities. for less complicated path, bore will be limited in four measurements: recommended bend limits, entry pit, minimum set back and minimum depth. Recommended bore limits must be considered during bore entry.

DIRECTIONAL BORING PROCESS

Recommended Bend Limit:

Though Drilling pipes are designed to bend, bending beyond recommended limits will cause damage that might not be seen. This damage adds up and can lead to sudden pipe failure.

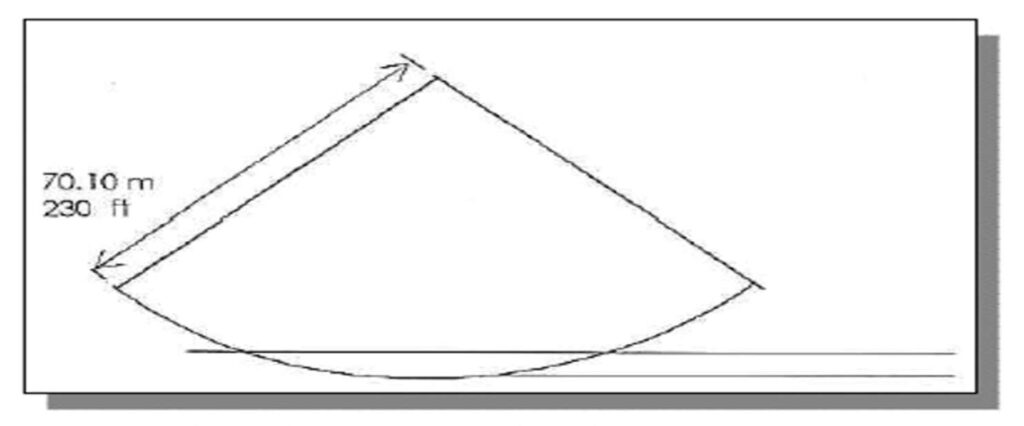

UFE 10,000T: These pipes have a tested bend radius of 230 ft (70.1m), measuring a 90-degree bend, whether during entry and exit or when turning, required 230 ft (70.1m) or forward distance and approximately 354 (54m) of pipe.

Use APPENDIX, sections A and B, to keep bends within safe limits and make sure pitch changes no more than 8% per UFE pipe.

Notice:

Bending pipe more sharply than recommended will damage pipe and cause failure over time.

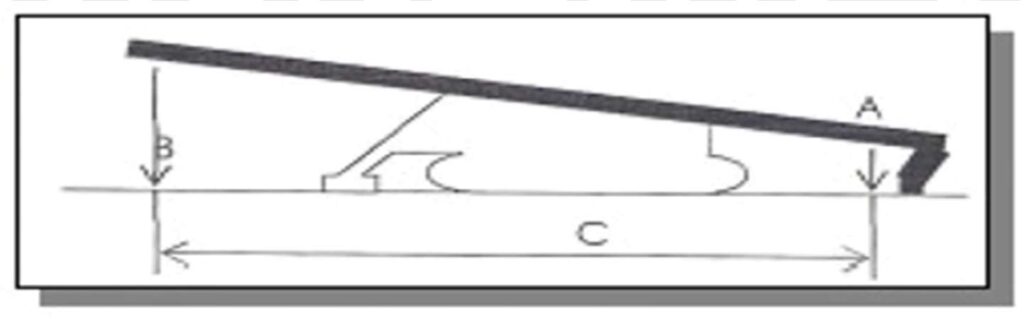

Entry Pitch is boring unit slope compared to slope of ground. Entry Pitch can be determined two:

1. Lay pitch beacon on ground and read pitch. Lay pitch beacon on beacon on boring unit and read pitch. Subtract ground pitch from boring unit pitch.

2. Measure from ground to front end of frame (A). Measure from ground to back end of frame (B). Subtract front measurement from back measurement to get rise. Measure distance between front and back point to be turn (C). Divide rise by run and multiply 100 to get pitch.

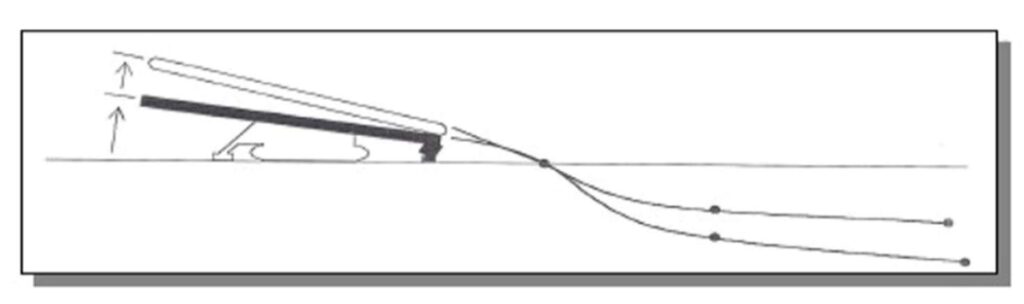

A Shallow entry pitch allows you to reach horizontal sooner and with less bending. Increasing entry pitch makes bore path longer and deeper.

Minimum Depth

Because pipe must be bent gradually, entry pitch and bend limits determine how deep the pipe will be when reaches horizontal. Use the chart in APPENDIX, section B, to determine minimum depth for your job.

To reduce depth, reduce entry pitch. To increase depth, increase entry pitch and set-back.

INFRAMAX is one of the pioneers of Horizontal Directional Drilling (HDD) in the U.A.E.

As techniques and working methods have improved, the Horizontal Directional Drilling operation has become a major contribution to the Non-Disruptive Road Crossing (NDRC) division.

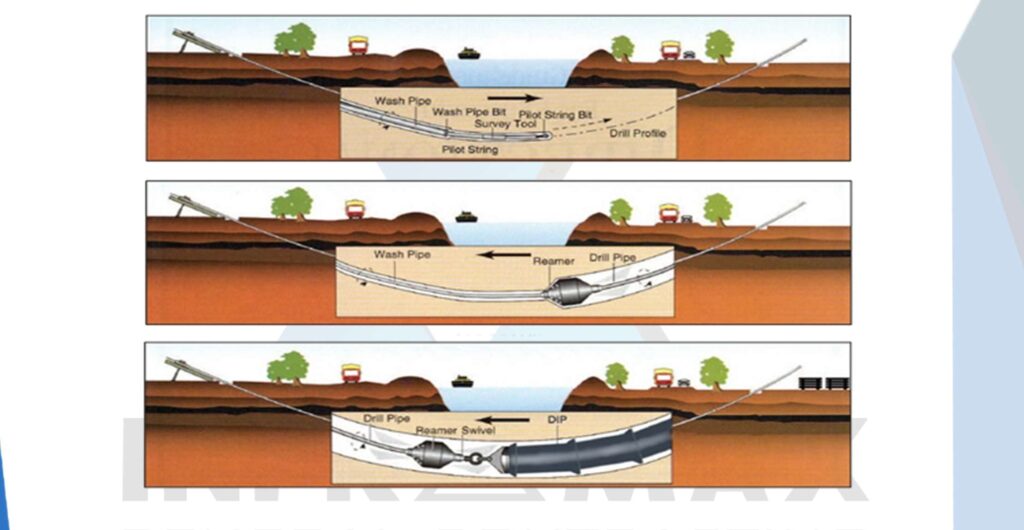

The process generally includes five distinct phases are as follows:

1. Planning, Preliminary survey.

2. Selecting the drilling units and drilling tools.

3. Drilling a small pilot bore hole, using technology that allows the drill to be steered and tracked from the surface.

4. Enlarging the hole by pulling back increasingly large reamers. (Back reaming or upsizing bore)

5. Pulling in the pipe.

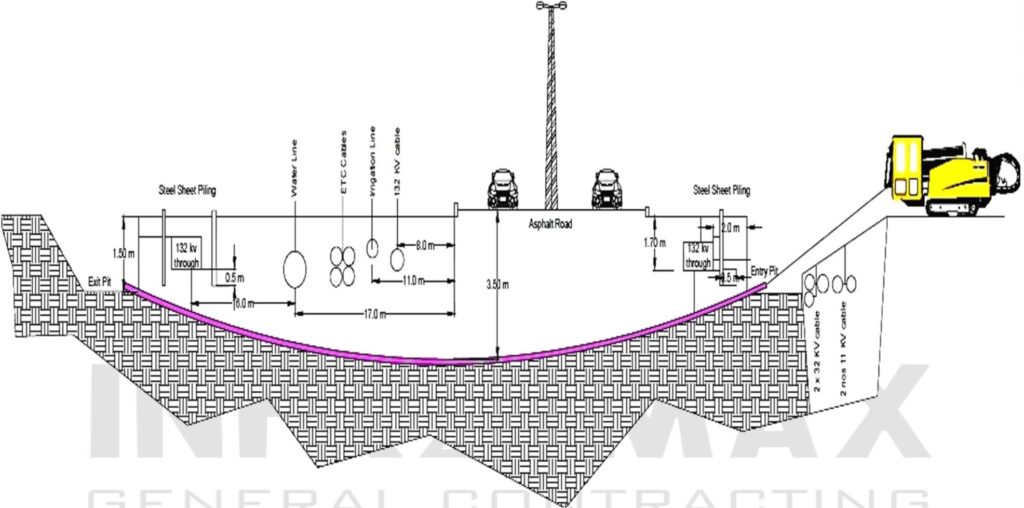

A well-planned HDD Operation includes preliminary survey of the bore path area, concerning other existing lines and the soil condition. Locating all existing services and plotting them on a drawing, then plan the best drilling path and include on the latest drawing to avoid all affected existing services.

The Choice of the drilling unit depends upon the bore length, the diameter of the pipe to be installed and the soil quality. It is important to choose the correct Drilling unit and tools for suitable bore length, and conditions. Site operation starts with drilling of the pilot hole from the surface on one side of the obstacle to be crossed. Continuous drilling.

Along a designed profile below and beyond the obstacle, and to exit at the surface on the other side drilling pilot bore hole. The pilot bore is launched from the surface at an angle between 5 and 15 degrees to the horizontal, and transitions to horizontal as the required depth was reached. A bore path of very gradual curvature or near straight alignment is normally followed to minimize friction and to stay within the allowable joint defection and the allowable bend radius for the pipe. This minimizes the chance of getting the pipe string ‘‘hung up’’ in the soil or damaging the pipe string.